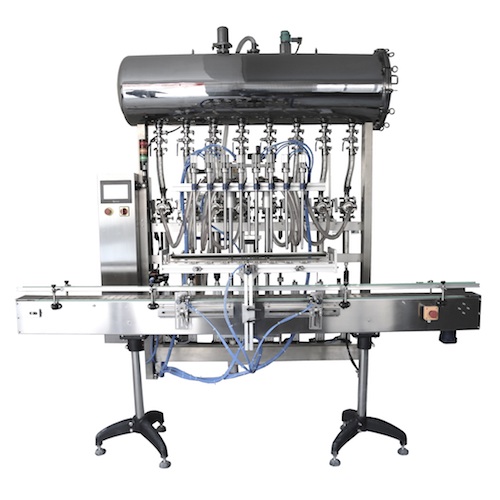

TotalPacks automatic cream piston fillers are suitable for a wide variety of products from water-thin to thick chunky products. Multiple filling nozzles as 2, 4, 6 or 8.

For sales inquiries please contact us via email sales@totalpacks.com or click the button below

Features

Siemens PLC control system and easy to use Touch screen technology(except for the 2 nozzles filler). German Festo pneumatic cylinders.

Variable speed drive ensures the machine smooth operation and makes it easy to adjust from one bottle size to another.

With 2, 4, 6 or 8 filling nozzles.

Diving nozzles are available to prevent bubbles formation during the filling process.

Shut-off nozzles help to optimize filling, no drips.

No bottle no filling mechanism.

A big tank at the top is with level sensor control.

All parts in contact with the filling material are made of stainless steel 316L to meet cGMP standard.

For the semi-automatic bench-top piston fillers, please click here FLC-150S / 250S Bench-top Piston Filler.

sales@totalpacks.com

sales@totalpacks.com +86 (577) 8870-2271

+86 (577) 8870-2271